Disaster

Plant Disaster Prevention

Challenge

- Plant Disaster Prevention Challenge

- Tunnel Disaster Response and Recovery

Challenge - Standard Disaster Robotics Challenge

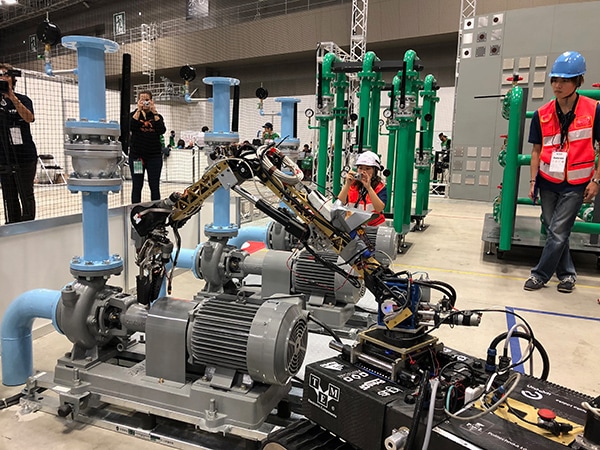

Plant Disaster

Prevention

Challenge

Inspecting or maintaining infrastructures based on set standards

(e.g. opening/closing valves)

(Competition time for each team is listed in the description of the video.)

Outline

Inspecting or maintaining infrastructures based on set standards

(e.g. opening and closing valves etc)

Task

Task P1

Task P1

Inspection and

Maintenance Task P2

Task P2

Fault Detection

and

Emergency

Response Task P3

Task P3

Diagnosis of

Pipes and

Ducts Task P4

Task P4

Diagnosis of

Tanks Task P5

Task P5

Overall Performance

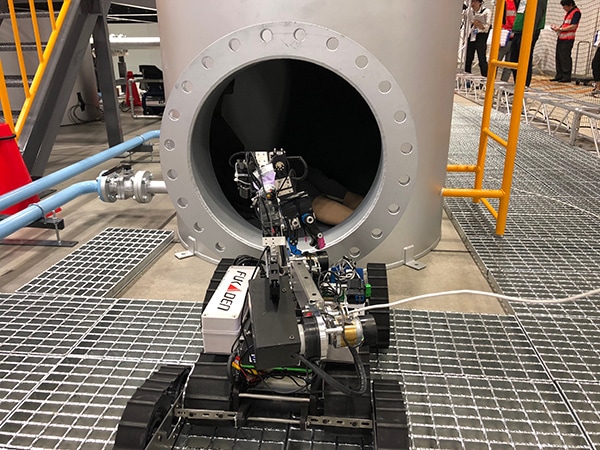

Task P1

Inspection and Maintenance

Read the meters installed at specified positions using a robot's camera, and adjust the corresponding valves etc.

Challenges

Feedback-type operation (read meters and adjust valves accordingly).

Task P2

Fault Detection and Emergency Response

Measure abnormal sounds and/or vibrations at unspecified positions on motors etc., and report the measurement results.

Operate the fire hydrant and fuel valves to extinguish a fire that occurred during the inspection.

Challenges

Fault detection of which the position is unknown.

Response to an unexpected emergency.

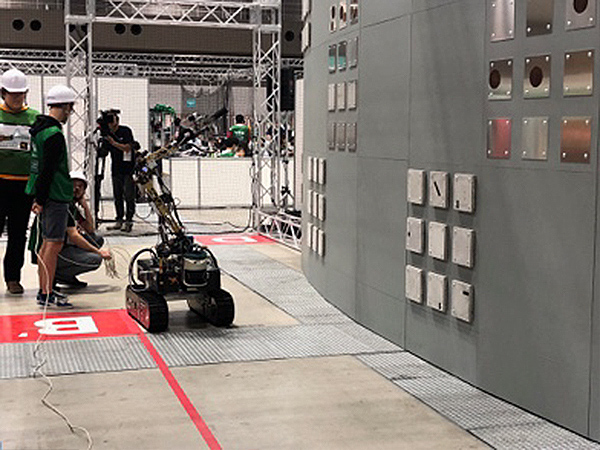

Task P3

Diagnosis of Pipes and Ducts

Diagnose the soundness (loose bolts, rust, etc.) of pipes and ducts within the plant.

Challenges

Inspection of complex structures. Speed and accuracy over a wide area is needed.

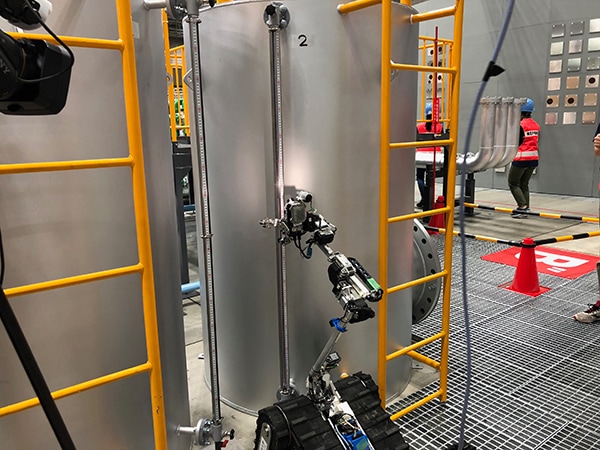

Task P4

Diagnosis of Tanks

Diagnose the soundness (cracks, rust, etc.) of large tanks within the plant.

Challenges

Inspection of large structures. Speed and accuracy over a wide area is needed.

Task P5

Overall Performance

Conduct a general inspection. When an emergency occurs, search for victims in adverse conditions (smoke, debris, etc.).

Challenges

A wide-range of operations in uncertain conditions.

- Plant Disaster Prevention Challenge

- Tunnel Disaster Response and Recovery

Challenge - Standard Disaster Robotics Challenge